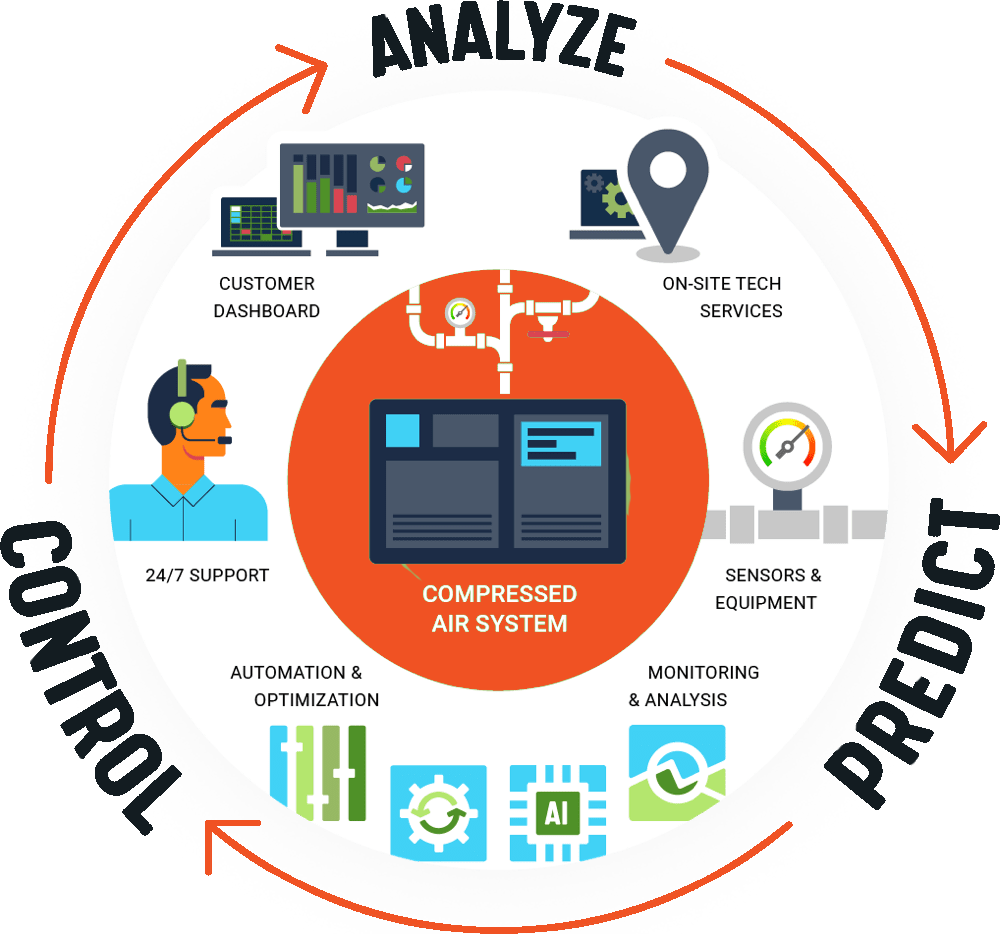

ECOPLANT Compressed Air, Cloud-Based Monitoring & Control System

At Team Air Power, we’ve seen it first-hand: solid compressors undermined by inefficient sequencing and poor control logic. That’s where Ecoplant comes in—AI that balances loads, detects leaks, and smooths pressure. The results speak for themselves: 10% better pressure stability, 35% less energy use, and a dashboard that’s actually used day to day.

Ecoplant transforms compressed air from a hidden cost into a managed utility. It reads live sensor data and adjusts operation in real time, reducing wasteful starts, idle time, and unnecessary energy use.

Installation is quick—one edge device, no PLC rewiring, and full compatibility with existing OEM equipment. Optimisation begins within 24 hours, with most sites seeing ROI inside 6 to 12 months. Maintenance teams benefit from early alerts that flag issues before they become downtime.

Up to 50 % Energy Saved

Site B previously ran 35% of each shift above 8.5 bar, with nightly spikes hitting 9.2 bar. After Ecoplant was installed, pressure now holds at 7.2 ± 0.1 bar with two machines idling offline—delivering €72k in annual savings and cutting 310 tonnes of CO₂-e emissions.

No guesswork, no gaps

Together with Ecoplant, Team Air Power provides clear, live insight into how your compressor room is running. That means faster decisions, better sequencing, and less energy waste. From pressure drops to irregular loads, issues are flagged before they escalate.

Compatible from day one

Ecoplant is brand-agnostic, integrating with almost any compressor fleet. Whether the setup is standard or mixed, the system fits in cleanly and starts delivering results. Monitoring is cloud-based, so your team can track performance from anywhere, on any device.